Construction

A wide choice of configurations, materials, options and accessories enables us to define the coils that meets your needs.

Tubes

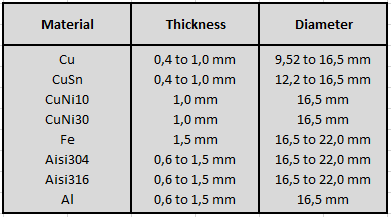

In order to be able to adapt our coils to all applications, fluids and pressure levels, our tubes are available in a wide range of diameters, thicknesses and materials.

- Copper, Tinned copper

- CuproNickel10, CuproNickel30

- Steel

- 304 stainless steel, 316 stainless steel

- Aluminium

Patterns

Coil patterns are defined by the diameter and arrangement of the tubes, which are crucial parameters in the search for the best technical solution to a given problem.

Air pressure drop vs. thermal performance.

Our range provides the optimum solution for every application.

Fins

In order to be able to adapt our coils to all applications, whatever the temperature, humidity and aggressiveness of the air or fumes, our fins are available in a wide range of materials and thicknesses

- Aluminium

- Copper, Tinned copper

- Painted aluminium

- AlMg 2.5

- 304 stainless steel, 316 stainless steel

- Steel

Fin spacing

The fin pitch is an essential parameter in thermal design.

Thin, it offers better thermal performance but is more sensitive to clogging and icing.

Wide, it offers better cleanability and resistance to icing but requires more rows to achieve performance.

The fin pitch is obtained by the collar, formed by the deformation of the metal during pressing.

The thickness and ductility of the material and the proximity of the tubes set the limit of possible deformation, and therefore of the fin pitch.

It is possible to push back this limit by forming an incomplete collar known as a ‘star collar’.

In this case, the tube between the fins is not completely covered by the collar.

Configurations

Headers

Any combination of materials and mechanical configurations can be adapted to suit your needs.

Connections can be standard (flange, thread) or by means of any type of special connection.

Drains and drains are standard.

- Steel

- 304 stainless steel, 316 stainless steel

- Copper

- Cupronickel

- Aluminium

Frames

Made to measure, it can incorporate a condensate drip tray or droplet separator.

Connection flanges, lifting lugs, plenums, diamond points, reinforced thickness and special profiles can all be envisaged for better integration on site.

- Galvanised steel

- Carbon steel

- 304 stainless steel, 316 stainless steel

- Copper

- Aluminium

Construction codes - Certifications

Our partners have ISO 9001:2015 quality certification.

Thermodynamic calculations are carried out using programmes developed in-house, adjusted and confirmed by measurements taken in their in-house measurement laboratory, which complies with ASHRAE standards.

Our partners have AHRI certification, which guarantees the performance of water heat exchangers, as well as ATEX and UL/CSA certification.

Each coil is manufactured in accordance with the EC directives, PED 2014/68/EU - Art 4.3 to Cat. IV Module H/H1.

Coils can be built to ASME VIII div.1 (with or without U-stamp), EN13445 or any other design code on request.

Heat exchangers can be designed and manufactured to withstand earthquakes or other accelerating conditions.

Finite element calculations can be carried out to verify mechanical strength, as well as noise and vibration calculations.

Our partners have brazing and welding qualifications to ASME IX, EN9606, EN15614, EN13585 and EN13134.

Non-destructive testing inspectors are certified to EN ISO 9712, SNT-TC-1A and ASME V.

Non Destructif Tests

Our partners are able to offer all types of non-destructive testing:

- Liquid penetrant testing

- Radio

- PMI

- Visual inspection

- Others on request

All types of documentary follow-up and inspections by third-party organisations are also possible.